Infrared Electrical Inspections have become a standard component of Electricians who are troubleshooting electrical issues, offering significant value at no additional cost. Residential and Commercial Electricians utilize infrared cameras to examine electrical panels for any signs of hot spots and shorts.

We spoke to several Electricians in the South West Florida area that commonly is affected by Storms and hurricanes about their troubleshooting methodology. Many have said Infrared scanning was a big factor in quickly pinpointing an overloaded circuit or short after water intrusions or floods.

Chris from Service Trade Pros, an Electrician in Naples Florida says, “we use infrared camera’s for finding the circuit that is hot in the panel, swapping it out and making sure that customers home is not going to catch fire”.

By turning on all electrical appliances in the home, Electricians can identify if there are any circuits that are overloaded or connections that are overheating.

Below you’ll see a quick overview of how industrial and commercial electricians use Infrared scanning to pinpoint exact breakers and circuits that are causing the issue.

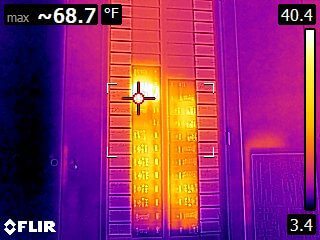

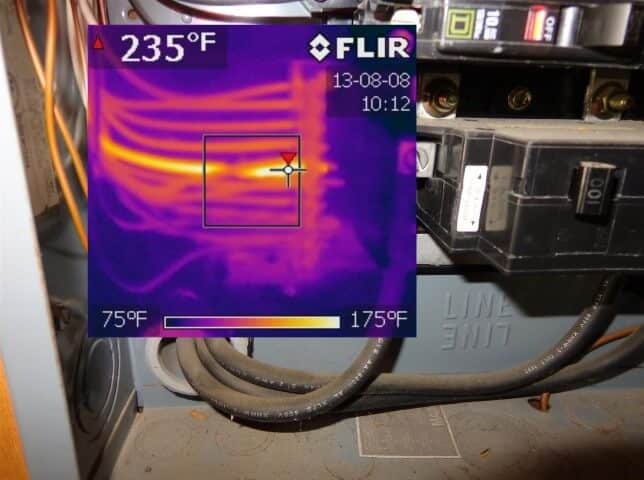

Using a high-end Flir infrared camera, quick scan can reveal any hot spots on the circuit breaker panel. When a hot spot is detected, the next step involves identifying whether it poses a problem.

The temperature of the circuit breaker isn’t the primary concern because it’s relative. For instance, even without any load, arc-fault circuit breakers tend to run a bit warmer than other breakers in the panel.

This, by itself, is not an issue.

Similarly, when using high-load devices like Electric ovens, Microwaves and Electric Ranges, it’s common for the breakers and wires to heat up as the appliances are pulling more amperage when in use.

Overloaded Circuits

However, problems often arise from overloaded circuits – in other words, when to many high wattage and high demand appliances are on the same circuit all working at the same time.

An example of this is an Electrical inspection of a newly built home in the winter, where a particular circuit breaker was considerably warmer than its surrounding breakers. The infrared camera measured the breaker’s temperature at nearly 70° Fahrenheit, while the ambient garage temperature was around 0°.

The critical factor to determine was whether the circuit was overloaded- this is where your Electrical meter comes into play.

Using a clamp meter, it was found that around 24 amps were flowing through a 20-amp circuit breaker, indicating excess load.

The acceptable continuous load for a 20-amp breaker is 80% of its rating, which equates to 16 amps. Thus, this circuit in the home was being overloaded and needed another circuit added to rectify the issue.

*Note – You’ll need to have your Electrician check if your actual wiring can handle the additional load if you decided to increase your Amperage on your Breaker, so most wiring is only rated up to a certain amperage rating.

Fire Hazards

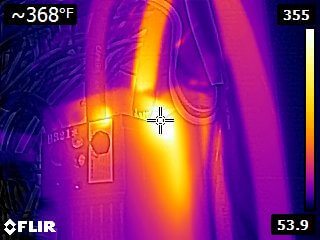

In some instances, wiring or circuit breakers are so hot that testing the amperage becomes unnecessary; these are identified as overheating and fire hazards.

This typically applies to circuit breakers or wires exceeding 140° Fahrenheit. According to UL 489 standards, the allowable temperature rise above ambient temperature is limited to 90°F.

Examples of Using Infrared to Find Hot or Overloaded Breakers

Above you’ll see a Very hot Circuit Breaker significantly warmer than surrounding breakers.

In this image below, the Electrician checked the Main breaker for the Breaker Panel and can see the infrared scope showing over 360 F!

Infrared cameras greatly aid in detecting issues in electrical panels. They help identify potential hazards efficiently, enabling prompt corrective measures. This technology is invaluable in preventing electrical fires and ensuring the safety of a home’s electrical system.

Flir makes some of the best Infrared cameras on the market, but they can be super spendy for those just getting started in the field.